SteelUp! aims to modernise the entire ArcelorMittal Long Products Luxembourg steelworks at Belval in order to supply low-carbon steel to Plant A at Rodange--the Bissen site aims to become WireSolutions’s first entirely “green” site by 2026--ArcelorMittal European Logistic Center became home to one of the country’s largest solar farms in 2024 with more than 8,600 photovoltaic panels on its roof--for newsreaders in Luxembourg it only takes a moment to realise how underrated these accomplishments are.

A global steel giant in the past, ArcelorMittal intends to remain one in the future, even if it means devoting research centres, millions of euros of investment and innovative ideas to the task. And while competition from Asia (especially China) and the United States is fierce for many of “our” manufacturers--because of their access to raw materials and electricity, and their human resource costs being lower--avant-gardism has become a state religion in Luxembourg, continually encouraged by successive governments in the name of the future and the environmental and digital transitions.

“Europe must have a strong industry”

Every last one of the high-tech industrial players understands the value of staying at the cutting edge within its own sub-subsector and having a niche. Look at Ampacet, a world leader in producing materials for special plastics; Ceratizit, which specialises refractory carbide solutions; Accumalux, which makes plastic components for batteries; Rotarex, a manufacturer of valves and pressure regulators for industrial and medical gases; Euro-Composites, specialist in composites and advanced materials; Paul Wurth and SMS Group, developers of automation solutions; or IEE, whose sensors can (for example) save the lives of babies sitting the backseat of a car.

We need to show our parent companies that Luxembourg can play a pioneering role.

“I absolutely want to maintain and develop all economic sectors in Luxembourg, including industry,” prime minister (CSV) said in his first interview after being elected. “Europe must have a strong industry. I’m very determined. And it’s easier in the current government, thanks to its composition, to ensure that businesses see the state as someone who will help them to develop.”

A bank of recycled materials

That latter comment was a jab at the former government, whom some perceived as being in the way in a context where the urgency of climate change is forcing us to think and produce in new ways . While ArcelorMittal has a natural interest in remaining at the cutting edge, a new generation of managers is coming to power. Some, like Maana Electric, intend to manufacture solar panels automatically from portable factories directly in the desert using sand--others, like Solarcleano, have developed modern-day “toys,” i.e. Ferrari-like cleaners that help ensure the longevity of those solar panels.

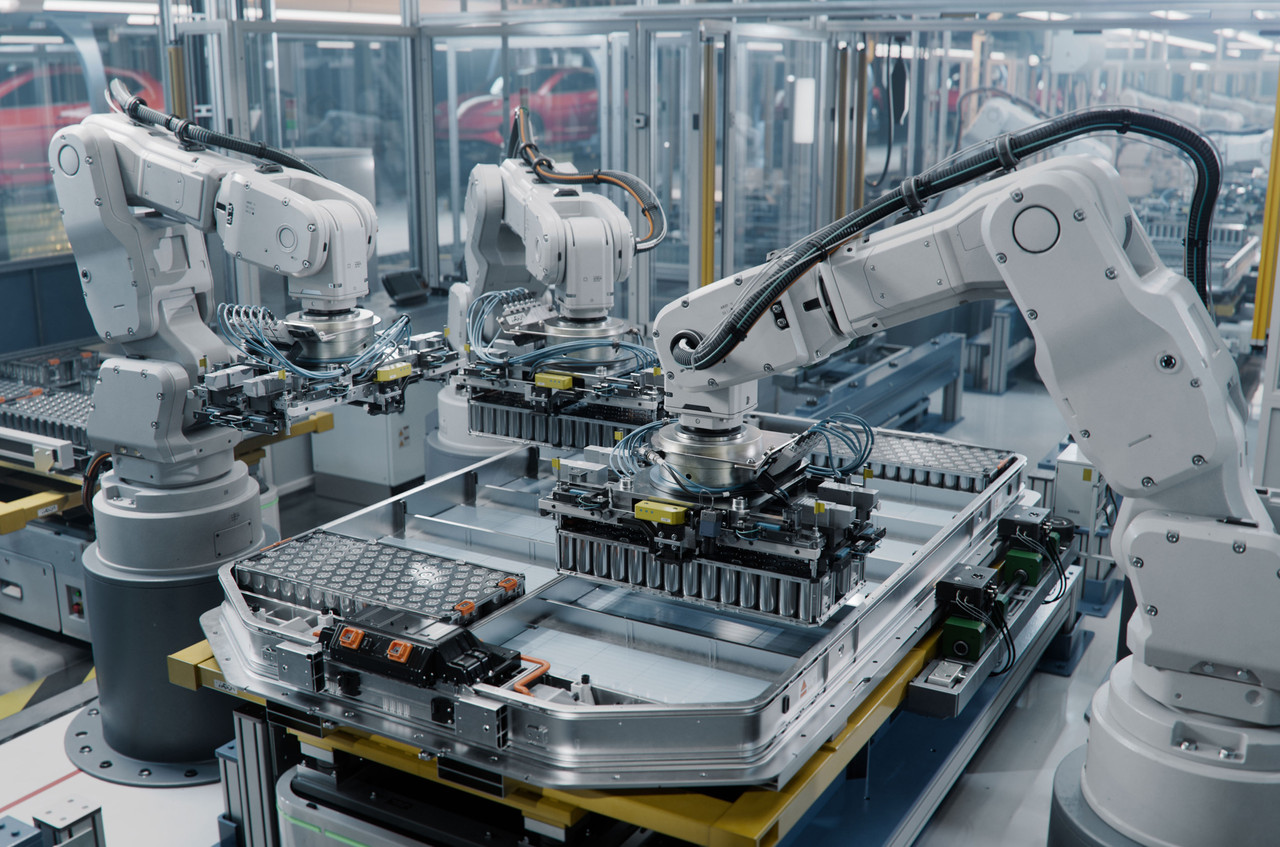

Meanwhile, Circu Li-ion has--like OQ Technology--been selected to join the European Innovation Council’s “Scaling Club” and is working to recycle the batteries used in the first generations of electric vehicles.

According to the Draghi report, developing the European Union's technological leadership could generate up to €4,000bn in added value for businesses by 2040… provided we get ahead of the game. Visual: Maison Moderne

And what can we say about Ocsial, a company born in Luxembourg but which has been forced to open its graphene nanotube factory--the first in the world--in Serbia? And Circuit Foil, the last copper wire manufacturing plant in Europe, who is fighting to stay?

Then you have AM 4 AM’s second additive manufacturing project--the 3D printing of high-added-value metal parts--which is now very well-funded and will continue its development, with Saturn Technology watching like a protective older sibling.

Predictability

Frieden said, at Fedil’s new year celebration, that he was going to suspend transposition of the CSRD directive pending the European Commission’s omnibus, which would bring together different pieces of legislation on the same subject to make them easier to implement. The head of government also invited manufacturers to name the regulations that are making their lives impossible, should the European Commission agree not only to a regulatory pause--Georges Rassel was proposing three years--but also to a clean-up of current regulations that have not had the desired effect. This is good news, but it undermines one of Luxembourg’s strengths: predictability. Entrepreneurs need to be able to plan for the medium- and long-term to decide to invest. And investing is crucial at the moment.

This article, , was written for the edition of Paperjam magazine, published on 29 January. The content is produced exclusively for the magazine. It is published on the website as a contribution to the complete Paperjam archive.

Is your company a member of the Paperjam Club? You can request a subscription in your name. Let us know via